Introduzione

Floor scrubbers are essential tools for commercial and industrial cleaning. They ensure large spaces remain spotless and safe. However, without a dependable battery, even the most advanced scrubber becomes just a heavy piece of equipment. In this guide, we will discuss different types of floor scrubber batteries, how to choose the right battery, and where to buy them. This guide is designed for facilities managers, procurement officers, and equipment dealers who need clear and actionable information to make the right battery choice.

Understanding the Basics of Floor Scrubber Battery

A floor scrubber battery is the heart of the machine—it doesn’t just provide electricity, it drives the entire cleaning process. The right battery choice directly impacts how long your scrubber can operate, how often it needs charging, and how reliably it performs over time. In commercial and industrial environments, where machines run for extended periods, batteries are engineered to handle frequent, deep discharges without rapid degradation.

Why it matters:

Selecting the correct battery ensures uninterrupted cleaning cycles, reduces costly downtime, and extends the overall lifespan of your equipment. Using an underpowered or mismatched battery can lead to reduced brush speed, poor water recovery, and more frequent maintenance issues.

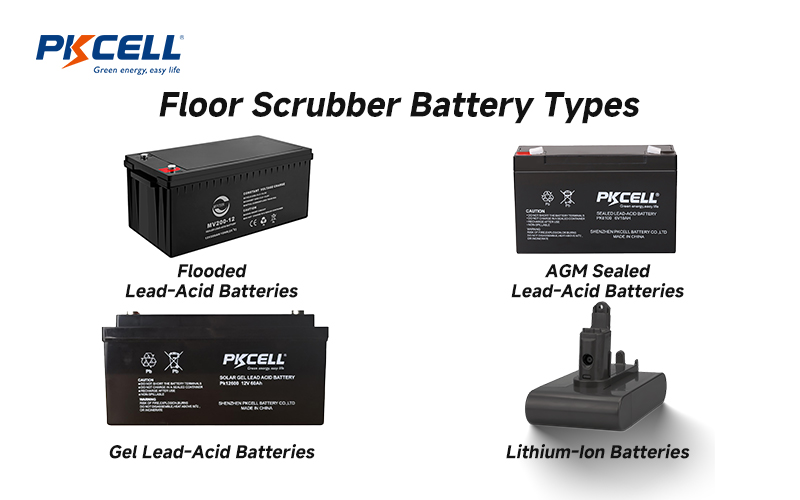

Different Types of Floor Scrubber Batteries

1. Flooded Lead-Acid Batteries

Specifications and Features:

Flooded lead-acid batteries are one of the oldest and most widely used energy storage solutions in floor scrubbers. These batteries typically offer a voltage of 6V or 12V per unit and are available in various amp-hour capacities to suit different runtime needs. They provide reliable performance under heavy load conditions and are cost-effective for large fleets, but they require dedicated maintenance routines.

Pros: Low upfront cost, proven technology, high availability.

Cons: Prone to acid spills, higher maintenance.

Ideal For: Budget-conscious operations with skilled maintenance staff.

Quote for PKCell Flooded Acid Battery

2. AGM (Absorbent Glass Mat) Sealed Lead-Acid Batteries

Specifications and Features:

AGM batteries use a fiberglass mat separator to hold the electrolyte in place. This design makes them spill-proof and more resistant to vibration. They are sealed units that do not require watering, which reduces downtime and maintenance. AGM batteries typically have lower internal resistance than flooded types, allowing for better charge acceptance and higher discharge rates. They are available in standard floor scrubber voltage ranges, usually 6V, 8V, or 12V, and are designed for moderate deep-cycle use.

Pros: Maintenance-free, spill-proof, better vibration resistance.

Cons: Slightly higher cost, shorter lifespan than gel or lithium in deep-cycle use.

Ideal For: Facilities needing reduced maintenance without moving to lithium.

3. Gel Lead-Acid Batteries

Specifications and Features:

Gel batteries use a silica-based gel to immobilize the electrolyte, creating a leak-proof design that is highly resistant to vibration and shock. They are optimized for deep-cycle performance. These batteries deliver consistent power over extended discharge periods. Gel batteries handle deep discharges better than AGM and have a longer cycle life when properly maintained. They are available in 6V, 8V, and 12V configurations and are ideal for environments where charging opportunities are limited.

Pros: Excellent deep-cycle performance, maintenance-free, long lifespan in proper conditions.

Cons: Higher cost than AGM, sensitive to overcharging.

Ideal For: Environments with deep discharges and infrequent charging opportunities.

4. Lithium-Ion Batteries

Specifications and Features:

Lithium-ion batteries, often built with lithium iron phosphate (LiFePO₄) chemistry for industrial applications, offer the highest energy density among floor scrubber battery options. They deliver consistent voltage throughout the discharge cycle and can be charged quickly without memory effect. Lithium batteries are lightweight, require no maintenance, and have an extended cycle life — often 3–5 times longer than lead-acid types. Most models include built-in battery management systems (BMS) for safety features such as overcharge, over-discharge, and thermal protection.

Pros: Lightweight, fast charging, less maintenance, long lifespan.

Cons: Highest upfront cost, may require compatible chargers.

Ideal For: High-usage environments needing maximum uptime and minimal maintenance.

How to Choose the Right Battery for Floor Scrubber?

When selecting a floor scrubber battery, especially in a B2B context, you need to consider:

- Machine Compatibility: Voltage, dimensions, and connector type.

- Usage Pattern: Daily hours of operation, number of shifts, and charging infrastructure.

- Budget & ROI: Balance between initial investment and total cost of ownership.

- Maintenance Capacity: Do you have staff trained for watering and equalizing flooded batteries?

- Environment: Temperature extremes can impact performance; lithium handles cold and heat differently than lead-acid.

Example: A 24V lithium-ion pack might cost more upfront but could last twice as long as AGM, require zero watering, and cut charging time in half—resulting in more uptime over the life of the machine.

Proper Maintenance Practices for Floor Scrubber Batteries

Storage and Disposal

To ensure optimal battery health, floor scrubber batteries should be stored in a cool, dry environment. Prolonged exposure to extreme temperatures—below 0°C or above 40°C—can significantly reduce performance and lifespan. When it comes to disposal, it is essential to follow proper environmental regulations. Lead-acid batteries are highly recyclable and should be sent to authorized recycling centers, while lithium-ion units require disposal through certified recycling facilities that can safely handle their chemistry.

How to Maintain and Extend Battery Life

For flooded lead-acid batteries, check the electrolyte levels at least once a week and top up with distilled water when necessary. Avoid “opportunity charging” (charging for short periods during idle time) unless you are using a lithium-ion battery, as lithium chemistry tolerates partial charging far better. Keep battery terminals clean and free from corrosion; a simple baking soda and water solution can be used for cleaning. Always recharge batteries fully after each use and avoid leaving them in a discharged state for extended periods, as this can accelerate capacity loss.

Common Battery Issues and Solutions

If your floor scrubber battery experiences a short runtime, it may be due to sulfation in lead-acid cells or diminished capacity in lithium-ion packs. In such cases, perform a capacity test and replace the battery if needed. Slow charging can result from an incompatible charger or loose cable connections, so always verify that the charger matches the battery type and check all connections. In multi-battery configurations, uneven cell voltage can cause imbalance and reduced performance; to prevent this, replace all batteries in the set at the same time to maintain consistent voltage and capacity.

Where to Buy Reliable Batteries for Floor Scrubber?

For B2B buyers, sourcing matters as much as the battery itself. PKCellsolution offers:

- Bulk Purchase Options: Ideal for fleets and distributors.

- Custom Solutions: Tailored battery configurations for specific scrubber brands.

- Technical Support: Guidance on installation, charging, and maintenance.

You can request a quote directly through our website, ensuring you get competitive pricing and technical expertise in one place.

Conclusione

In industrial cleaning, battery choice directly impacts productivity and cost control. By understanding the basics, comparing types, selecting based on your operational needs, and applying proper maintenance, you can ensure your floor scrubbers deliver peak performance. The right supplier—one who understands your B2B requirements—can make that process seamless and cost-effective. So contact PKCell today!

FAQs

Q1: How long should a floor scrubber battery last?

Most lead-acid scrubber batteries last 3–5 years with proper care. Lithium-ion options can exceed 7 years, especially in high-utilization environments.

Q2: Can I replace lead-acid batteries with lithium in my existing scrubber?

Yes, many scrubbers can be retrofitted with lithium packs, but ensure voltage, dimensions, and connector compatibility. Some may require a charger upgrade.

Q3: How often should I charge my scrubber battery?

Charge after every shift. For lithium-ion, partial charges are fine, but lead-acid batteries should be charged fully to prevent sulfation.

Q4: Why is my new battery not holding a charge?

This could be due to charger incompatibility, a faulty battery, or storage damage before installation. Always test upon delivery and use the correct charger.

Q5: What’s the best battery for heavy daily use?

Lithium-ion is ideal for high-intensity operations due to its fast charging, long cycle life, and low maintenance requirements.