Powering Through Crisis: A European Auto Manufacturer’s Backup Power Solution

A major automotive manufacturing plant in Western Europe, renowned for its precision engineering, faced a severe production challenge. The facility relies on high-precision auto parts lathes to produce a key component for its vehicles. However, the intensifying Russia-Ukraine war began to destabilize the regional energy grid, leading to increasingly frequent and unpredictable power fluctuations and outages.

This instability had a direct and damaging impact on the factory’s manufacturing process. The sensitive lathes, vulnerable to sudden power loss, began producing components with inconsistent tolerances. The quality fell below the stringent standards required, failing to meet the factory’s own high expectations. The situation escalated critically when, in recent months, three formal customer complaints were directly linked to the faulty component.

Faced with a mounting quality crisis, the manufacturer was forced to take drastic action. They halted the entire production line for that specific component and urgently diverted all customer orders to their sister facilities in other countries.

Engineering a Resilient Solution

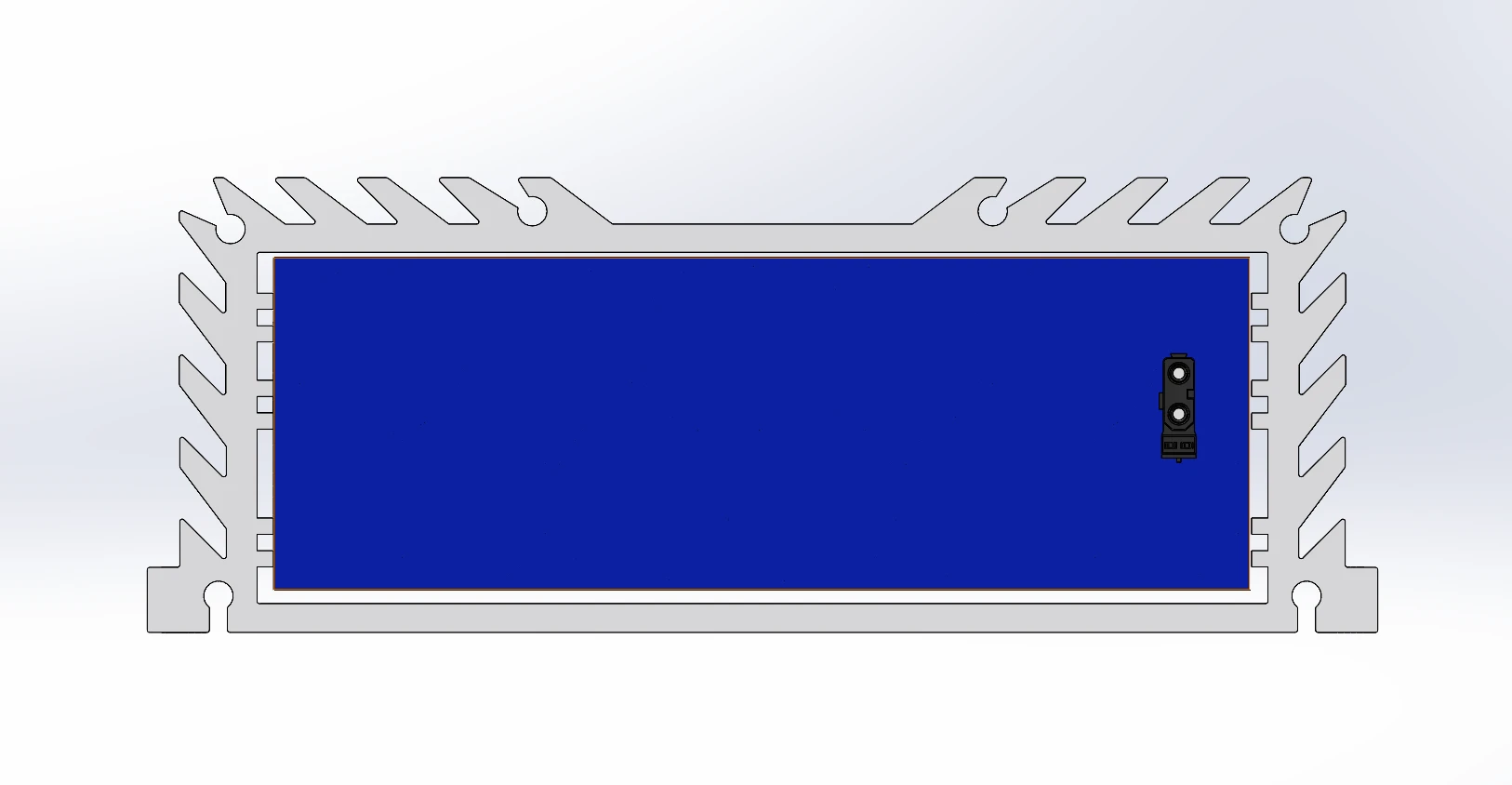

To solve the problem at its source, the factory’s engineers devised a plan to integrate a backup power supply directly into the lathes. This system would provide instantaneous power in the event of an outage, allowing the machines to complete their cycles without interruption, thereby preserving quality. They contacted our team with a specific request: a custom, metal-housed lithium-ion battery pack compact enough to be mounted directly onto the machine. The housing itself had been pre-designed by PKCELL.

Our initial proposal prioritized safety, including a robust cell holder to secure the individual battery cells. However, we immediately identified a conflict: the pre-designed metal housing was too small to accommodate both the battery cells and the safety holder.

Our structural engineers devised an ingenious solution: a misplaced placement design. This innovative approach cleverly reoriented the cells within the holder, solving both problems simultaneously. It maintained the critical safety features of the cell holder while reducing the overall assembly’s footprint, allowing it to fit perfectly within the compact PKCELL metal box.

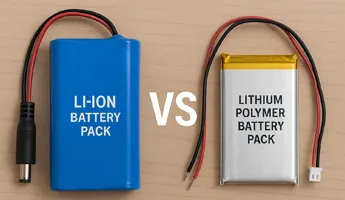

For the core cell itself, we recommended the LG M50LT, selected for its superior quality, proven reliability, and excellent value. Beyond the product, we built confidence by conducting a comprehensive series of tests in our lab, simulating real-world conditions to ensure the solution’s viability before even sending samples. This rigorous pre-validation earned significant trust from the client.

A Successful Roll-Out and Global Expansion

The results were immediate and decisive. The sample units passed all factory tests successfully. The backup power system integrated seamlessly with the lathes, maintaining perfect operation through simulated power cuts, and the client was thoroughly satisfied.

With the solution validated, the manufacturer first placed an order for a small batch to be distributed to their global factories, proactively preventing similar production halts elsewhere.

The success of this project did not stop there. Following the successful small-batch implementation, the company placed a large quantity order to equip their entire production line with this new backup system. Furthermore, impressed by the results, they have begun recommending the system to their machine suppliers, setting a new industry standard for resilience. This partnership not only resolved an immediate crisis but also forged a new path toward sustainable and disruption-free manufacturing.

Customer Case: Backup Power Supply Solution for Industrial Machines

Project Background

This case took place in Western Europe, where a car manufacturer uses precision CNC lathes to produce key automotive components.

In recent years, the Russia–Ukraine conflict has led to unstable regional electricity supply, causing frequent power interruptions and voltage fluctuations.

As a result, the factory suffered from reduced machining accuracy and unstable product quality, which led to three customer complaints in just a few months.

To prevent further losses, the company had to suspend one production line and temporarily shift orders to overseas factories.

Key Challenges

- Unstable Power Supply:Frequent power outages caused machine stops and data loss during operation.

- Limited Space:The backup power unit needed to be installed inside the machine, within a compact metal enclosure.

- High Safety Requirements:The battery must withstand high temperature and vibration conditions typical of industrial environments.

- Performance Consistency:Each backup system had to ensure identical performance across multiple machines to maintain product tolerance.

Our Solution

細胞選擇

We recommended the LG M50LT lithium-ion cells, featuring high energy density, long cycle life, and excellent discharge performance—ideal for providing instant power during outages.

BMS Design

- Integrated overcharge, overdischarge, short-circuit, and overcurrent protections;

- Included temperature monitoring and cell balancingfor long-term stability;

- Added a signal output interfaceto communicate with the machine’s main controller, enabling smart power-fail protection logic.

Structural & Thermal Design

- The metal housing was custom-designed by PKCELL, offering strong impact resistance and efficient heat dissipation;

- Initially, a cell holder was proposed for added safety, but space constraints made it infeasible;

- Our structural engineer implemented a misplaced cell arrangement, achieving both secure cell fixationand compact size to fit perfectly into the metal box.

Production & Testing

- Conducted comprehensive electrical and mechanical tests, including vibration, thermal rise, and power loss recovery validation;

- The prototype passed customer verification tests, successfully maintaining machine operation during power interruptions;

- Each battery pack underwent 48-hour aging testsand was assigned a unique traceability code to ensure quality tracking.

Results & Value

- Production Continuity Improved:Machines kept running smoothly during power loss, maintaining part accuracy.

- Quality Stability Restored:Customer complaints dropped to zero, with overall yield significantly improved.

- Optimized Space Utilization:Innovative internal design reduced installation volume by 15%.

- Enhanced Reliability:Passed high-temperature and impact resistance tests, meeting industrial-grade standards.

Next Steps

The solution has now entered mass production, with the customer implementing it across all global manufacturing sites.

They have also invited us to co-develop a high-power UPS battery system for their next-generation heavy industrial machinery.

“This backup system completely solved our power failure issue. Our machines now operate stably, product quality has returned to expectations, and the compact design makes installation simple and efficient.”