Meeting and Exceeding Industry Standards

Industry-Recognized Custom Battery Certifications

Pkcell's Comprehensive Certifications (IEC, CE, RoHS,MSDS, UN38.3, UL, CB, KC, PSE) Guaranteeing Quality, Safety, and Reliability for Your Custom Lithium Battery Needs !

Why Pkcell is the Right Fit for your Project

Your Partner in

Custom Battery Solution

-

Certified Quality for

Custom BatteriesOur custom lithium batteries are manufactured to the highest standards, evidenced by IEC, CE, RoHS, and UN38.3 certifications. This ensures top-tier safety, reliability, and performance for your demanding applications -

Tailored Lithium

Battery Innovation30+ Lithium Battery R&D Engineers. We innovate and customize to deliver lithium battery solutions perfectly tailored to your application, offering OEM/ODM services. -

Collaborative Custom

Battery SolutionsFrom concept to delivery, we are your dedicated partner. We prioritize a customer-centric approach, ensuring your custom lithium battery solution meets your technical specifications. -

Premium lithium CellsTo ensure exceptional performance and longevity in your custom lithium batteries, we feature high-quality cells from leading brands like Samsung, LG, SunPower, Dmegc, BAK, and EVE.

Custom Lithium Battery Solutions

Tailored Services for Your Project

-

High-Quality Cell SelectionExpert Cell Selection: Lithium-ion, LiPo, LiFePO4 & More

-

Voltage & Capacity CustomizationTailored V, Ah, C-Rate for your specific needs

-

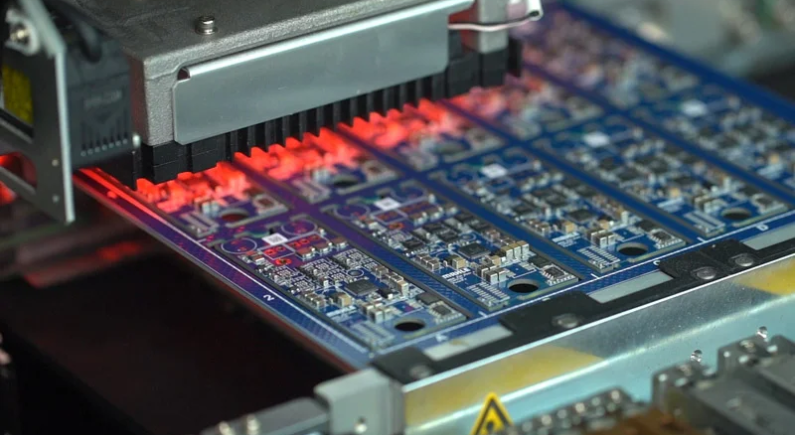

Advanced BMS IntegrationOptimized Performance & Safety For Device Applications

-

Safety RedundancyMulti-layer Protection Mechanisms

-

Hardware + Software CoordinationAdvanced Protection & Diagnostics

Customization Process

Customization Process

-

Feasibility Analysis and Project

Initiation- Assessment

- Technical Evaluation

- Feasibility Confirmation

-

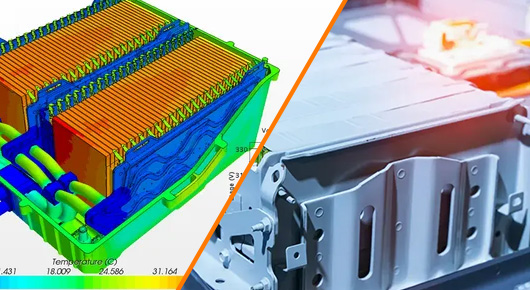

Product Design and Review

- Electrical Design

- Mechanical Design

- Process Design

-

Design Validation and Review

- Internal Design Review

- Feasibility Assessment

- Risk Assessment

- Design Modification (if needed)

-

Sample Testing

- Capacity test

- Cycle life test

- Discharge rate test

- Safety performance test

-

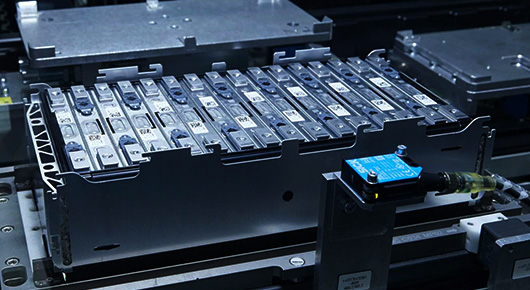

Mass Production

- Contract signing

- Mass production

- Quality control

-

Delivery and Acceptance

- Packaging and shipping

- Acceptance testing

- After-sales service

Innovation Driven