Related Case

Application Scenario

Products offer

-

Powerful PerformanceLithium-ion technology delivers high power output for demanding tasks like drilling, cutting, and sanding.

-

Long RuntimeHigh-capacity batteries provide extended runtimes, reducing downtime and increasing productivity.

-

Durable and ReliableTough construction withstands impacts, vibrations, and temperature variations, ensuring long-term reliability.

-

Fast ChargingQuickly recharge batteries with fast charging technology, minimizing downtime and maximizing work time.

You must consider the following information when you want to customize electric tool battery

-

Battery Pack

RelatedVoltage (V):Match the battery voltage to your tool’s requirements. Higher voltage generally means more power.

Capacity (Ah): Higher capacity provides longer runtime but may increase weight.

Discharge Rate (C-rating):A higher C-rating allows for greater current draw, supporting more powerful tools and demanding applications.

Chemistry:Li-ion batteries are the most common choice for power tools due to their high energy density and performance.

Cycle Life:Choose a battery with a long cycle life to reduce the need for frequent replacements.

-

Electric Tool

SpecificationsTool Type and Power Demands:Different tools have varying power requirements. High-drain tools like circular saws and impact drivers need batteries with higher capacity and discharge rates.

Runtime Needs:How long do you need the tool to operate on a single charge? This will influence the battery capacity (Ah).

Ergonomics and Weight:Consider the weight and size of the battery pack, especially for handheld tools, to ensure comfortable and balanced use.

Environmental Conditions:If you’ll be using the tools in extreme temperatures or harsh environments, choose a battery with a suitable operating temperature range.

Custom Lithium Battery Solutions

Tailored Services for Your Project

-

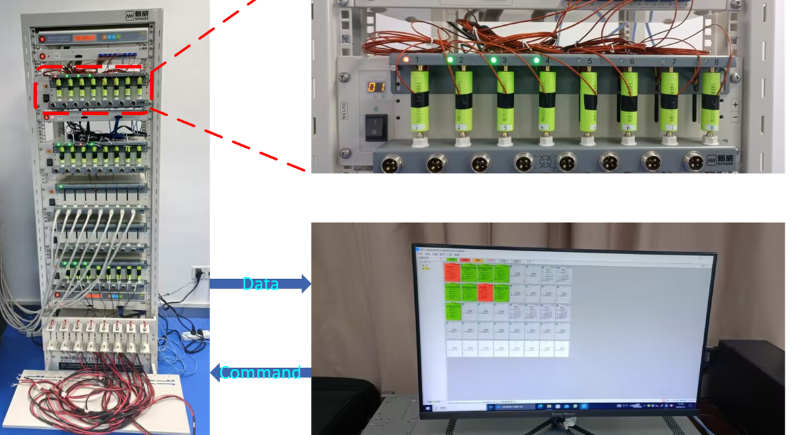

Assembly Process

-

Testing Process

Customization Process

Customization Process

-

Feasibility Analysis and Project

Feasibility Analysis and Project

Initiation -

Product Design and Review

Product Design and Review -

Design Validation and Review

Design Validation and Review -

Sample Testing

Sample Testing -

Mass Production

Mass Production -

Delivery and Acceptance

Delivery and Acceptance