Related Case

Application Scenario

Products offer

-

Extended Cleaning TimeCover more ground and clean for longer with PKCELL floor scrubber batteries designed for extended runtimes.

-

Reliable Performance for Demanding TasksEnsure consistent power and efficient cleaning, even with heavy-duty scrubbing, with our durable and high-quality floor scrubber batteries.

-

Safe and Worry-Free OperationClean with confidence knowing our batteries feature advanced safety features and protection systems to prevent accidents and ensure operator safety.

-

Maintenance-Free ConvenienceFocus on cleaning, not battery maintenance, with our long-lasting, maintenance-free battery options.

You must consider the following information when you want to customize Floor Scrubber battery

-

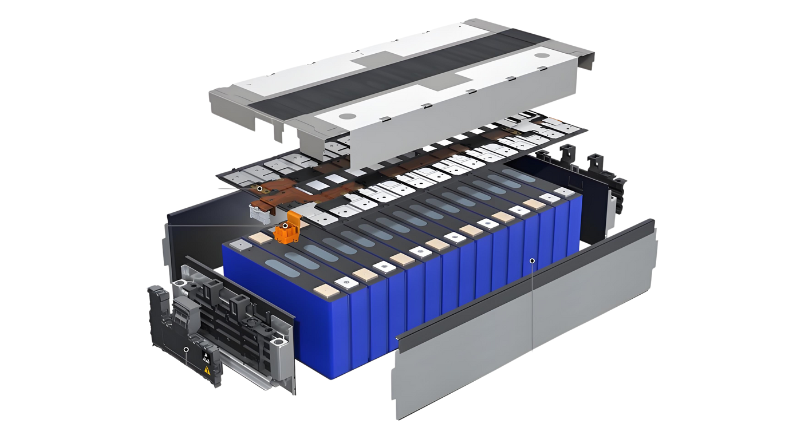

Battery Pack

RelatedVoltage (V):Ensure the battery voltage matches your floor scrubber’s requirements. Common voltages include 24V, 36V, and 48V.

Capacity (Ah):A higher Ah rating provides longer runtimes between charges.

Discharge Rate (C-rating):A higher C-rating allows for greater current draw, supporting powerful motors and efficient cleaning.

Chemistry:Li-ion batteries are gaining popularity due to their lighter weight, longer lifespan, and higher energy density compared to traditional lead-acid batteries.

Cycle Life:Choose a battery with a long cycle life to reduce the need for frequent replacements.

-

Floor Scrubber

SpecificationsScrubber Size and Type:Different floor scrubber models have varying voltage and power requirements. Consider the size and type of your scrubber (walk-behind, ride-on) as this will influence the battery selection.

Cleaning Area and Frequency:Larger cleaning areas or frequent use will require batteries with higher capacity and discharge rates.

Runtime Needs:How long do you need the scrubber to operate on a single charge? This will determine the necessary battery capacity (Ah).

Terrain and Floor Type:Consider the types of floors you’ll be cleaning (smooth, rough, carpeted) and any inclines or obstacles, as these can affect power demands.

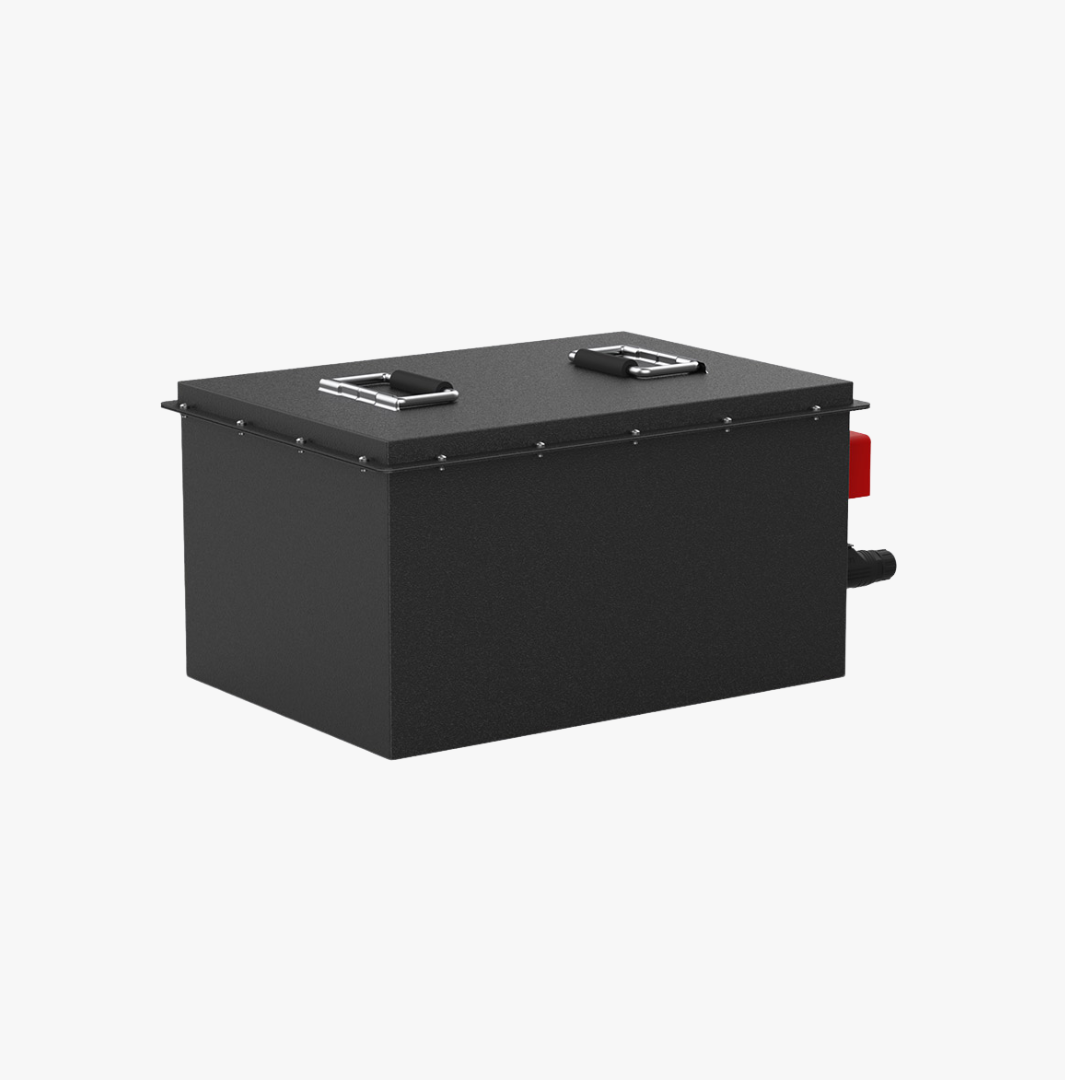

Custom Lithium Battery Solutions

Tailored Services for Your Project

-

Tailored Structural DesignSeamless Integration With Your Applications

-

Durable Custom Enclosure DesignFrom Lightweight Plastics to Rugged Metal

-

Advanced Thermal ManagementKeeping Your Batteries Performance & Lifespan

Customization Process

Customization Process

-

Feasibility Analysis and Project

Feasibility Analysis and Project

Initiation -

Product Design and Review

Product Design and Review -

Design Validation and Review

Design Validation and Review -

Sample Testing

Sample Testing -

Mass Production

Mass Production -

Delivery and Acceptance

Delivery and Acceptance