Related Case

Application Scenario

Products offer

-

Extended Oxygen SupplyBreathe easier for longer with PKCELL oxygen generator batteries designed for extended operating time, providing uninterrupted oxygen flow.

-

Reliable Performance for Critical NeedsCount on consistent power delivery and stable voltage output for reliable oxygen concentration, even during extended use.

-

Lightweight and Portable for Freedom of MovementEnjoy greater mobility and independence with our lightweight battery solutions, making it easier to carry and use your oxygen generator on the go.

-

Enhanced Safety for Peace of MindBreathe with confidence knowing our batteries are equipped with advanced safety features to protect against overcharging, over-discharging, and short circuits, ensuring the safe and reliable operation of your oxygen generator.

You must consider the following information when you want to customize Oxygen Generator Battery

-

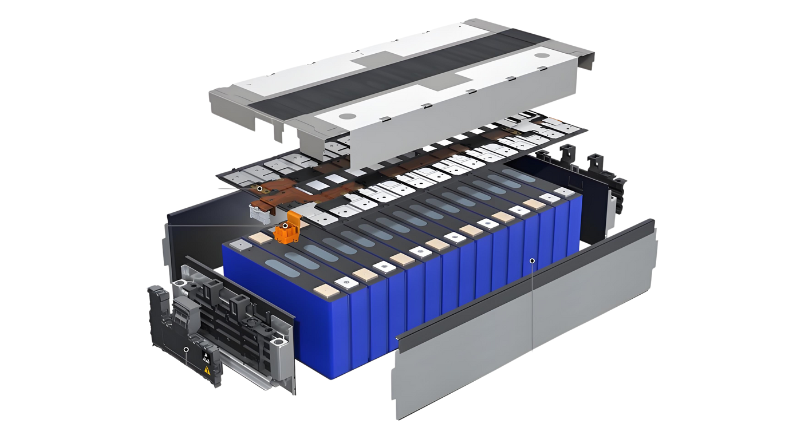

Battery Pack

RelatedVoltage (V):Match the battery voltage to your POC’s requirements. Common voltages for POCs include 12V, 14.4V, and 28V

Capacity (mAh): Higher capacity provides longer operating time between charges.

Discharge Rate: The battery should be able to provide sufficient current to power the POC’s oxygen concentration process.

Chemistry: Li-ion batteries are the standard for POCs due to their high energy density, lightweight design, and long lifespan.

Cycle Life:Choose a battery with a long cycle life to reduce the need for frequent replacements.

-

POC

SpecificationsPOC Model and Compatibility: Different POC models have specific battery voltage and connector requirements. Ensure compatibility with your device.

Oxygen Flow Rate and Usage Patterns: Higher oxygen flow rates or continuous use will require batteries with higher capacity (mAh) for longer runtimes.

Portability Needs: Consider the weight and size of the battery pack, especially if you’ll be carrying the POC frequently.

Operating Environment: If you’ll be using the POC in extreme temperatures or demanding conditions, choose a battery with a suitable operating temperature range.

Custom Lithium Battery Solutions

Tailored Services for Your Project

-

Tailored Structural DesignSeamless Integration With Your Applications

-

Durable Custom Enclosure DesignFrom Lightweight Plastics to Rugged Metal

-

Advanced Thermal ManagementKeeping Your Batteries Performance & Lifespan

Customization Process

Customization Process

-

Feasibility Analysis and Project

Feasibility Analysis and Project

Initiation -

Product Design and Review

Product Design and Review -

Design Validation and Review

Design Validation and Review -

Sample Testing

Sample Testing -

Mass Production

Mass Production -

Delivery and Acceptance

Delivery and Acceptance