Related Case

Application Scenario

Products offer

-

Extended Operation TimeKeep your AGVs running longer and maximize productivity with PKCELL batteries designed for extended operation time.

-

Reliable Performance for Demanding TasksEnsure consistent power and efficient operation, even with heavy loads and continuous use, with our durable and high-quality AGV batteries.

-

Optimized for AutomationStreamline your automated workflows with our lightweight and compact battery solutions, designed to fit seamlessly into your AGV designs.

-

Enhanced Safety in the WorkplaceOperate your AGVs with confidence knowing our batteries are equipped with advanced safety features to prevent accidents and ensure workplace safety.

You must consider the following information when you want to customize AGV battery

-

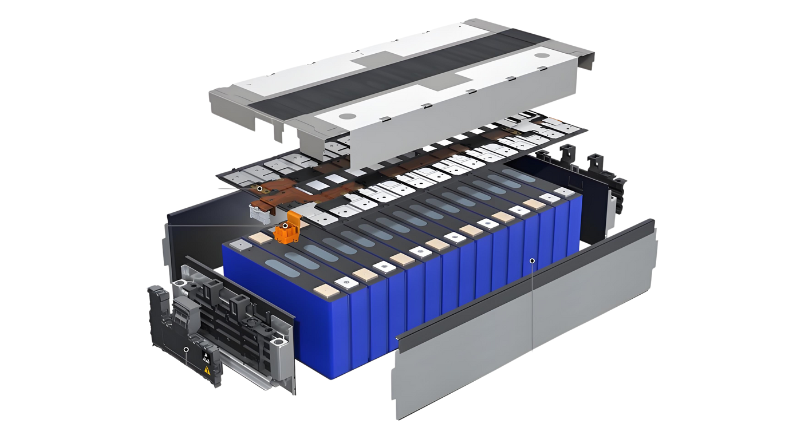

Battery Pack

RelatedVoltage (V):Ensure the battery voltage matches your AGV’s requirements. Common voltages include 24V, 36V, 48V, and 80V.

Capacity (Ah):A higher Ah rating provides longer runtimes between charges.

Discharge Rate (C-rating):A higher C-rating allows for greater current draw, supporting heavy payloads and demanding tasks.

Chemistry:Li-ion batteries are gaining popularity for their lighter weight, longer lifespan, and faster charging times compared to traditional lead-acid batteries.

Cycle Life:Choose a battery with a long cycle life to reduce the need for frequent replacements.

-

AGV

SpecificationsAGV Type and Payload:Different AGV models have varying voltage and power requirements. Consider the type of AGV (unit load carrier, tugger, forklift AGV) and its payload capacity, as this will influence the battery selection.

Operating Environment:Will the AGV be used indoors or outdoors? Extreme temperatures, dust, moisture, or harsh chemicals can affect battery performance and lifespan.

Navigation and Duty Cycle:The complexity of the AGV’s navigation and the frequency of its operation will influence the required battery capacity and discharge rate.

Charging Infrastructure:Evaluate your charging options (opportunity charging, battery swapping) and available charging time to minimize downtime and optimize efficiency.

Custom Lithium Battery Solutions

Tailored Services for Your Project

-

Tailored Structural DesignSeamless Integration With Your Applications

-

Durable Custom Enclosure DesignFrom Lightweight Plastics to Rugged Metal

-

Advanced Thermal ManagementKeeping Your Batteries Performance & Lifespan

Customization Process

Customization Process

-

Feasibility Analysis and Project

Feasibility Analysis and Project

Initiation -

Product Design and Review

Product Design and Review -

Design Validation and Review

Design Validation and Review -

Sample Testing

Sample Testing -

Mass Production

Mass Production -

Delivery and Acceptance

Delivery and Acceptance